INDOOR

BANNERS

- available in different sizes

- rolled up, lightweight, easy to transport

- high-quality printouts on a wide range of materials

- typical finishing methods:

- top, bottom: tunnels + two round stiffening battens

- string to suspend the banner

- sides: double stitching

- the battens eliminate flapping in moderate

puffs of wind indoors

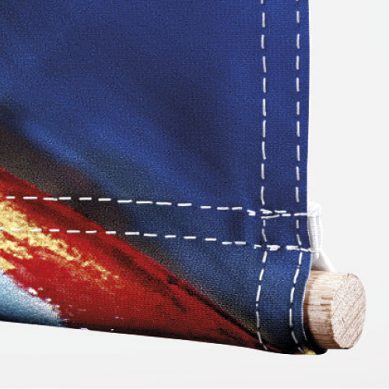

FINISH

Banner top

Banner bottom

Double stitch

STAGE AND EVENT

ARRANGEMENTS

- it is possible to fabricate very large printed

arrangements by means of joining many gores,

e.g. stage and trade fair decors, sports stadium flags,

theatrical and television sets, and artwork arrangements

for mass events - printed with the use of direct sublimation or UV process

(single gore width of up to 3.2 m and 5 m, respectively) - printing on many different materials is possible

- finishing method – as per customer's individual order

MEGA-PRINTOUTS AVAILABLE TO ORDER

Previous image

Next image

BACKLIGHT BANNER

- a coated matt-finished material characterised

with excellent light diffusion and transmission properties - two-sided UV printing process

(with vertical mirror image on reverse side) - maximum width of artwork in single gore 495 cm

- the printout looks the same during the daytime

(without backlighting) as at night-time

(“day/night” feature) - material very resistant to tear and wear, moisture,

UV radiation, and both low and high temperatures - intended mainly for framing

- typical finishing methods:

- cut to format

- welded tunnel

- sewn-on Keder with round core

TYPICAL FINISHING OPTIONS

EXCELLENT FOR BACKLIT ADS

Cut to format

Keder with round core

Welded tunnel

BLOCKOUT BANNER

- available in different sizes and finish options

- weldable material allows to obtain large advertising surfaces;

maximum width of artwork in single gore 320 cm - a coated material with an interlayer preventing the artwork from

being seen from reverse side - thanks to inner separator, banners do not show through even

on sunny days and are perfectly readable - particularly suitable for two-sided printing

- allows to obtain high-quality printouts characterised

with high resistance to tearing and fraying - can be used both indoors and outdoors

- typical finishing methods:

- cut to format

- weld along perimeter + an eyelet each 50 cm

- welded tunnel

- sewn-on Keder with round core

TYPICAL FINISHING OPTIONS

DIFFERENT ARTWORK ON EACH OF BANNER SIDES

Cut to format

Welded edge + eyelets

Welded tunnel

Sewn-on Keder

CONTACT

Katarzyna Kurzeja

katarzyna.kurzeja@studiokolor.com.pl

phone: +48 17 860 05 20

mobile: +48 662 353 102

katarzyna.kurzeja@studiokolor.com.pl

phone: +48 17 860 05 20

mobile: +48 662 353 102